Which type of activated carbon is suitable for me?

In case you are not sure as to which type of activated carbon best to your needs, then please contact us. we can provide you with free technical support and solutions.

If you need to test the performance of activated carbon first, please take the opportunity to contact us for free samples.

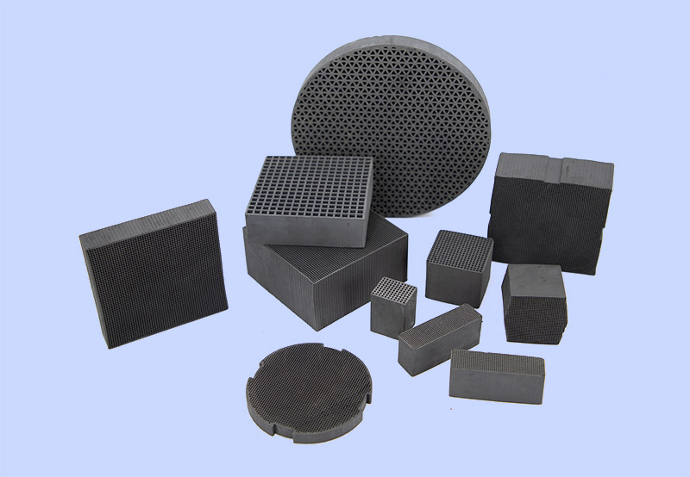

Honeycomb activated carbon has a relatively large area, microporous structure, high adsorption capacity. It is high surface activated carbon products, and is widely used in air pollution control and water treatment. The honeycomb activated carbon adsorption method is adopted, that is, the exhaust gas is in contact with the porous activated carbon having a large surface.

Deoiling Naphthalene Removal Agent.

Deoiling Naphthalene Removal Agent.

Deoiling naphthalene removal agent is made of high-quality coal-based activated carbon, added with special active agents and additives. It is used for high-precision naphthalene removal and de-oiling adsorption purification of gas sources such as steel plant coke oven gas, coking plant gas, and city gas.

Impregnated activated carbon is selected from high quality activated carbon with high adsorption performance, impregnated with silver, copper oxide, phosphoric acid, KOH, NaOH and so on, and then refined by 130°-180° cremation. Impregnated activated carbon is widely used to sterilizationin the water and remove organic gases and vapors from air or other gas streams, such as hydrogen sulfide, H2S, HCN, phosphine and arsine, etc.

This adsorbent media is 50/50 percent blend of potassium permanganate ball and activated carbon pellet. Potassium permanganate ball is optimum adsorption for gaesous contaminants. Our Activated carbon is a pelletized activated carbon, which is designed for a broad range of contaminants and concentrations. They are mixed together, which makes it very deal for the removal of hydrogen sulfide, formaldehyde, ethylene, medium to high molecular weight VOCs, and low volatility organic contaminants.

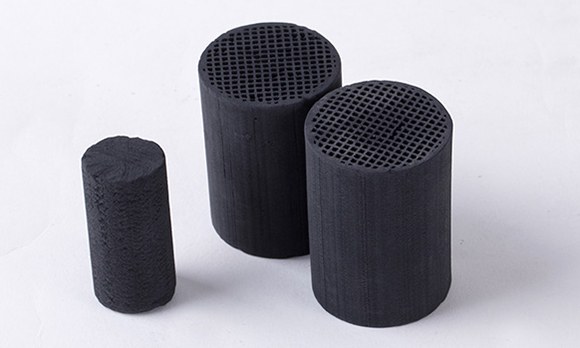

Sulphur Impregnated Activated Carbon for Mercury RemovalSulfur impregnated activated carbon is cylindrical particles with dark apperance. It is produced through a series of fine processing such as screening, batching, crushing, molding, carbonization, activation, impregnation and drying. This type of impregnated activated carbon is mainly used in the removal of mercury vapour from natural gas, air, hydrogen or other gas, which has been approved superior removal effect.

Sulphur Impregnated Activated Carbon for Mercury RemovalSulfur impregnated activated carbon is cylindrical particles with dark apperance. It is produced through a series of fine processing such as screening, batching, crushing, molding, carbonization, activation, impregnation and drying. This type of impregnated activated carbon is mainly used in the removal of mercury vapour from natural gas, air, hydrogen or other gas, which has been approved superior removal effect.

Catalyst for the synthesis of vinyl chlorideActivated carbon mercury catalyst is widely used in the synthesis of PVC raw materials. Without the application of activated carbon mercury catalyst, the cost of PVC raw materials will be greatly increased, which will directly cause the higher price of PVC, and directly affect the scope of PVC usage.